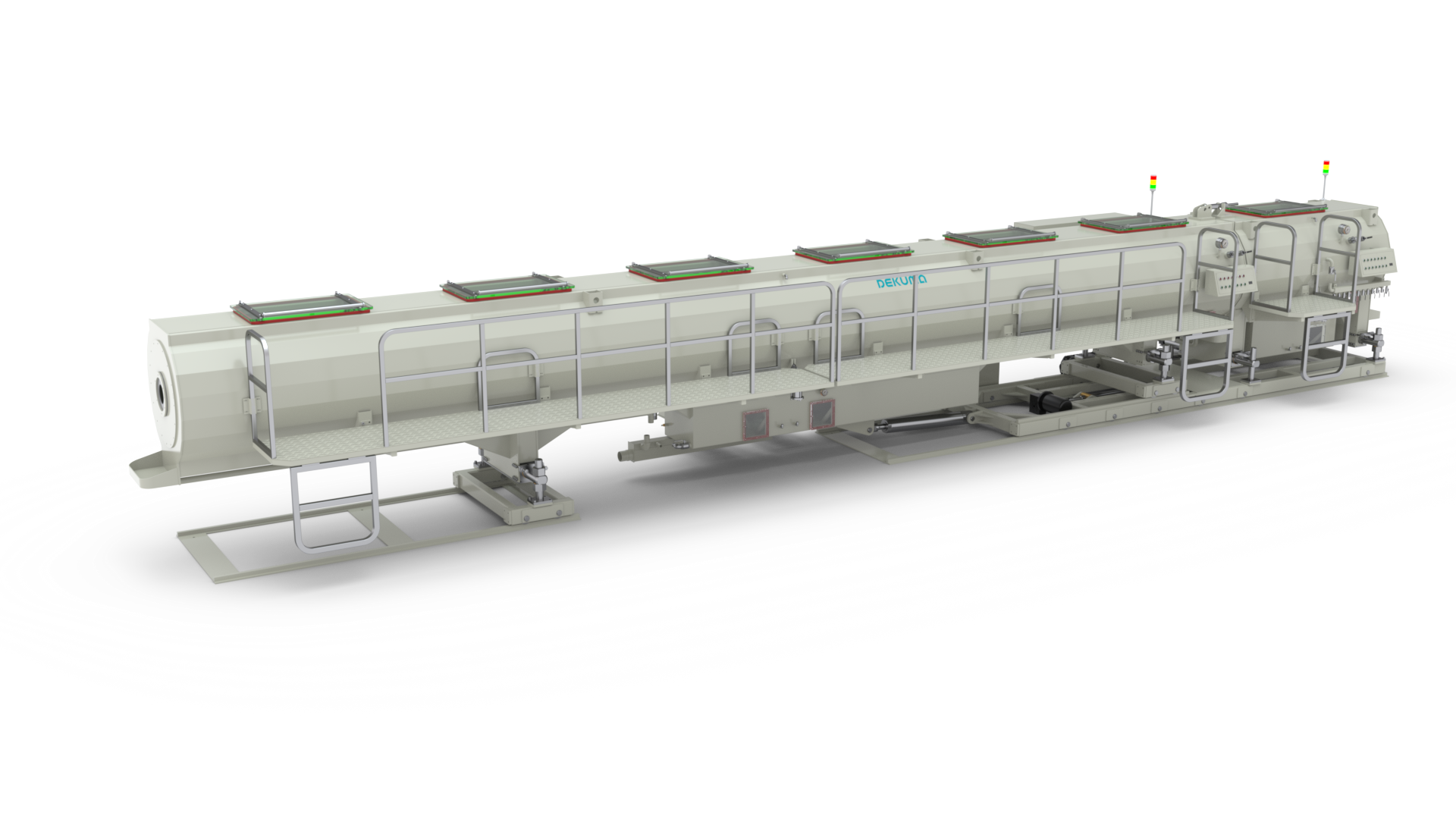

Leveraging advanced technology to streamline PE pipe extrusion is key for manufacturers—and Dekuma’s PE pipe extruding machine stands out as a solution that blends performance and reliability. As a brand focused on industry-specific needs, Dekuma designs its PE pipe extruding machine to support consistent PE pipe extrusion, with core components engineered by German teams to meet strict standards. This ensures the machine operates smoothly over long production cycles, minimizing downtime while maintaining uniform pipe quality—a critical factor for businesses aiming to boost output without sacrificing precision.

Key Components Enhancing Extrusion Performance

Dekuma’s PE pipe extruding machine includes parts that optimize PE pipe extrusion. Its single screw extruder offers nine diameter options (45mm–150mm) and multiple L/D ratios, allowing customization for different pipe sizes. The extrusion die head, suitable for HDPE, reduces melt pressure and temperature to lower pipe stress, while high-quality ceramic heaters extend the machine’s service life. These components work together to ensure efficient, stable PE pipe extrusion for various applications.

Adapting to Diverse Material Needs

A standout feature of the PE pipe extruding machine is its strong adaptability to materials like PE, PPR, and PE-RT. This versatility means manufacturers can use the same equipment for multiple PE pipe extrusion tasks, reducing the need for additional machinery. Dekuma’s focus on material flexibility aligns with its goal of providing customized solutions that fit diverse production requirements.

Conclusion

Dekuma’s PE pipe extruding machine elevates PE pipe extrusion through German-engineered precision and material adaptability. For manufacturers seeking efficiency and reliability, this machine delivers consistent results, reinforcing Dekuma’s reputation as a provider of high-quality extrusion solutions.